interpack 2026: LoeschPack and Hastamat demonstrate integrated packaging solution

09/02/2026, Lahnau

When packaging machines interact perfectly

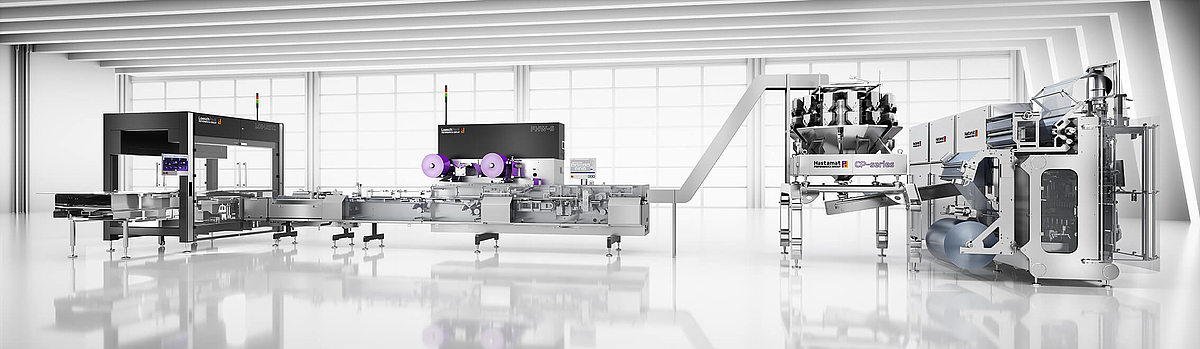

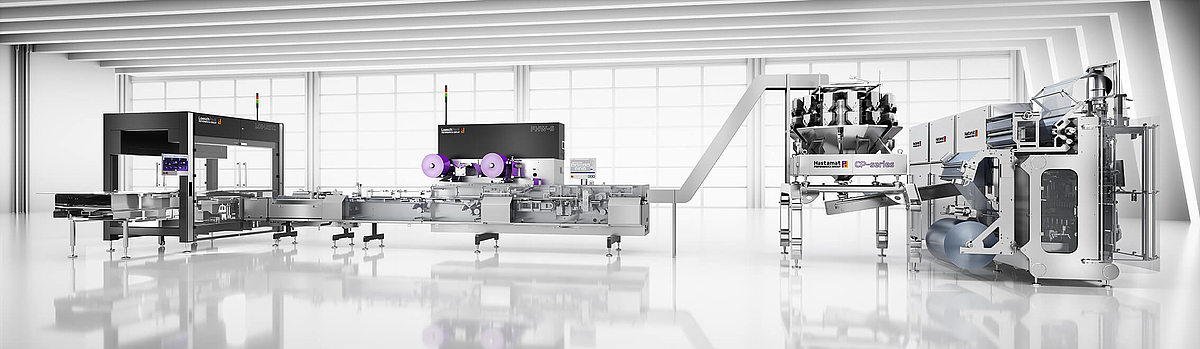

From 7 to 13 May 2026, LoeschPack and Hastamat will be showing efficient and sustainable packaging solutions for the food sector at the world-leading interpack trade fair in Dusseldorf. On the joint stand in hall 14, C22, the German packaging machine manufacturers will be showing a fully integrated packaging line and further new items from their range for the first time. The focus is on continuous packaging processes from a single source – from primary packaging to the supermarket shelf.

The joint packaging line from Hastamat and LoeschPack will be premiered at interpack 2026. Multiple machines perfectly integrated to each other will demonstrate live how rectangular products are packaged efficiently, precisely and in a manner which is gentle on the product and material – from feeding to packaging tubular bags, weighing, dosing and packaging in the sustainable block bottom bag. In addition, both companies will be showing a wide range of machines and complete packaging line systems for different packaging steps and sectors. "We provide our international customers with specific packaging solutions which are tailored specifically to their products and requirements. True to our company pledge 'Packaging your ideas…', we realize the ideas of our clients – from the individual machine to the complete packaging line", says Olaf Piepenbrock, Executive Partner of Hastamat, LoeschPack and the Piepenbrock business group.

Tailor-made packaging lines from a single source

The combined Line of the LOMATIC feed and distribution system and LoeschPack's FHW-S optimized horizontal flow-wrap system with the CP14 multi-head weigher and Hastamat's new KBM block bottom bag machine. All the packaging materials used are recyclable and support sustainable packaging concepts. LoeschPack's and Hastamat's close cooperation pursues a clear goal: that of providing food manufacturers with individually engineered packaging systems from a single source. By pooling their technological expertise, the sister companies develop tailor-made solutions which are designed for the exact product, process and production environment. "Instead of standardized concepts, we produce integrated lines with which we provide complete solutions for the individual challenges our customers face. In the process, our common guiding principle 'Packaging your ideas...' stands for maximum customer partnership – from the first idea to the completed packaging line", says Dr. Ferdinand Schwarzfischer, Chief Technology Officer at LoeschPack.

Feeding and distributing products efficiently

The LOMATIC, with its modular construction, feeds downstream machines in all output ranges, and achieves up to 190 rows per minute in the process. At interpack, alongside rectangular products, it will also be distributing chocolate, biscuits, waffles and cereal bars. The hygienic design facilitates simple cleaning and fast format changes while maintaining a compact footprint – a clear advantage for flexible production environments.

Optimized flow-wrap packaging

With the new FHW-S machine generation, LoeschPack will be introducing a particularly compact, maintenance-friendly and easily accessible flow-wrap machine. The horizontal machine for cold and hot sealing applications runs without external compressed air, thus reducing energy and operating costs notably. Simplified operation, the optimized film web control and reliable and fast format changes increase the production reliability and reduce downtimes. In combination with a high-performance infeed specific to the respective project, the FHW-S packages up to 2,100 products at a film speed of up to 205 meters per minute – even with alternative, paper-based packaging materials. Additionally, modern 3D product checks make for constantly high product and packaging quality.

Weighing technology for the highest precision

After primary packaging, Hastamat takes on the pre-packaged products and feeds them to the CP-14 multi-head weigher. The fully automatic combination weigher facilitates precise, reliable weighing and counting. Both bulk and stick-shaped products can be dosed on the same machine, depending on the design. With up to 140 weighments per minute, it provides the perfect combination of efficiency and high flexibility, short changeover times and maximum dosing accuracy for the widest range of applications.

New block bottom bag solution for varied products

Hastamat is reviving its KBM series again with the new block bottom bag machine. The particularly versatile packaging system produces square sealed bags with exactly formed bases. The empty bags which are pre-fabricated on the vertical form-fill-seal machine, are filled and sealed on a horizontal conveyor belt. At the same time, the KBM processes different bag head shapes on a single machine – for example, as an upright header with clip or folded over once or multiple times and secured with a label or adhesive strip. "Our new, improved machine can be used flexibly for many products, it fits in seamlessly in complete packaging lines and can be controlled jointly with our multi-head weigher. The short drop distances of this machine are perfectly suited to our weighers as a packaging combination for sensitive products. The modular construction with the individual processing stations of the new machine facilitates optimum adaptation to bag shapes and outputs. We will be demonstrating just how this all works in practice at interpack where the KBM will be packaging the products counted on the multi-head weigher, the top edges of which are folded and secured with an adhesive label", explains Thomas Bornemann, Director Sales & Marketing at Hastamat.