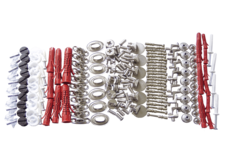

Ordering and counting stick-shaped products – our counting systems are the ideal solution. That's because the ZA offers optimum and individual packaging solutions for all industrial sectors. For food and non-food, for both rugged and fragile items. It packages them with affection. Even particularly long products. Always accurate to exact unit, always gentle. And it makes sure that only truly flawless items are placed in the respective packaging, in a manner that is as reliable as it is efficient. At a high processing speed of up to 70 dosings per minute/lane. It doesn't matter whether synchronised or unsorted: The product counting machine directs everything into ordered lanes. After all, you want things to run smoothly.

With our fully automatic counting and packaging machine, you have more security and reliability when counting your stick-shaped products. Contact us now and find out more – for individual solutions which are just right.

Special benefits:

- Unproblematic integration into the overall plant

- High flexibility with product dimensions and product types

- Intelligent sensor checking of products for breakage detection with automatic ejection

„Monitoring stick-shaped products is a challenge. The Hastamat counting systems sort and count them for exact quantity and quality control. They make sure that the products are transferred to the next step in a controlled manner which is also gentle on the product.“

Philippe Mavic Sales Manager at Hastamat

Your benefits with our product counting system

However your products arrives at the counting machine: The upstream sorting device of the ZA aligns them in good time. Using timing hoppers, bucket conveyors or feed chutes. In the process, the items are also checked by sensors. That way, it detects…

However your products arrives at the counting machine: The upstream sorting device of the ZA aligns them in good time. Using timing hoppers, bucket conveyors or feed chutes. In the process, the items are also checked by sensors. That way, it detects broken sticks and ejects them immediately. The counting system knows no bounds. Just accurate quantities and tendency control weighing. And the system does all this simultaneously so that there is no delay.

Just counting is not enough? No problem – our stick counting systems for stick-shaped products can be individually adapted and upgraded to suit your requirements. To include infeed, storage and transfer devices. With which you can transfer the sticks…

Just counting is not enough? No problem – our stick counting systems for stick-shaped products can be individually adapted and upgraded to suit your requirements. To include infeed, storage and transfer devices. With which you can transfer the sticks via an elevator into vertical tubular bags, for example. Or into cans. Or trays. And the ZA can also mix different product types. And process extra long sticks. For flexibility in the packaging.

Be ready for anything – with our ZA. Because the product counting system is not just simple to operate, it also monitors all system parts. In addition, its modular construction provides the ideal conditions for quick product adjustments. And…

Be ready for anything – with our ZA. Because the product counting system is not just simple to operate, it also monitors all system parts. In addition, its modular construction provides the ideal conditions for quick product adjustments. And individual servo motor driven belts which can be replaced in a jiffy. And they're maintenance-free too.

Have any questions about our solutions?

Find out local representative

Service that is there for you

Well looked after all-round

From development to installation and subsequent support: With our service team, we are there for you at all times. In order to solve problems and develop new packaging processes. For your success. And preferably together with you.

Find out more about our complete service.

End-to-end packaging lines

Being set up flexibly to needs and requirements, being able to offer the best packaging quality and ensuring smooth processes – we engineer our complete packaging lines with these aims. And together with you. So that individual production processes are implemented in the optimum manner. For more efficiency and cost-effectiveness.

Find out about our innovative system solutions with gentle product handling – looking at the system examples of our complex packaging lines.

The right solution for everything

Constructing counting systems is one of our specialist fields. We can do even more